A home is a big wooden box and a shipping container is a big steel box. Each was designed to play a very specific, yet different roles, but both rely on the same basic engineering principle to work successfully.

How a structure’s loads are transferred through the structure and down to the ground are the foundation of any building or structural design, regardless of material. This is called a load path.

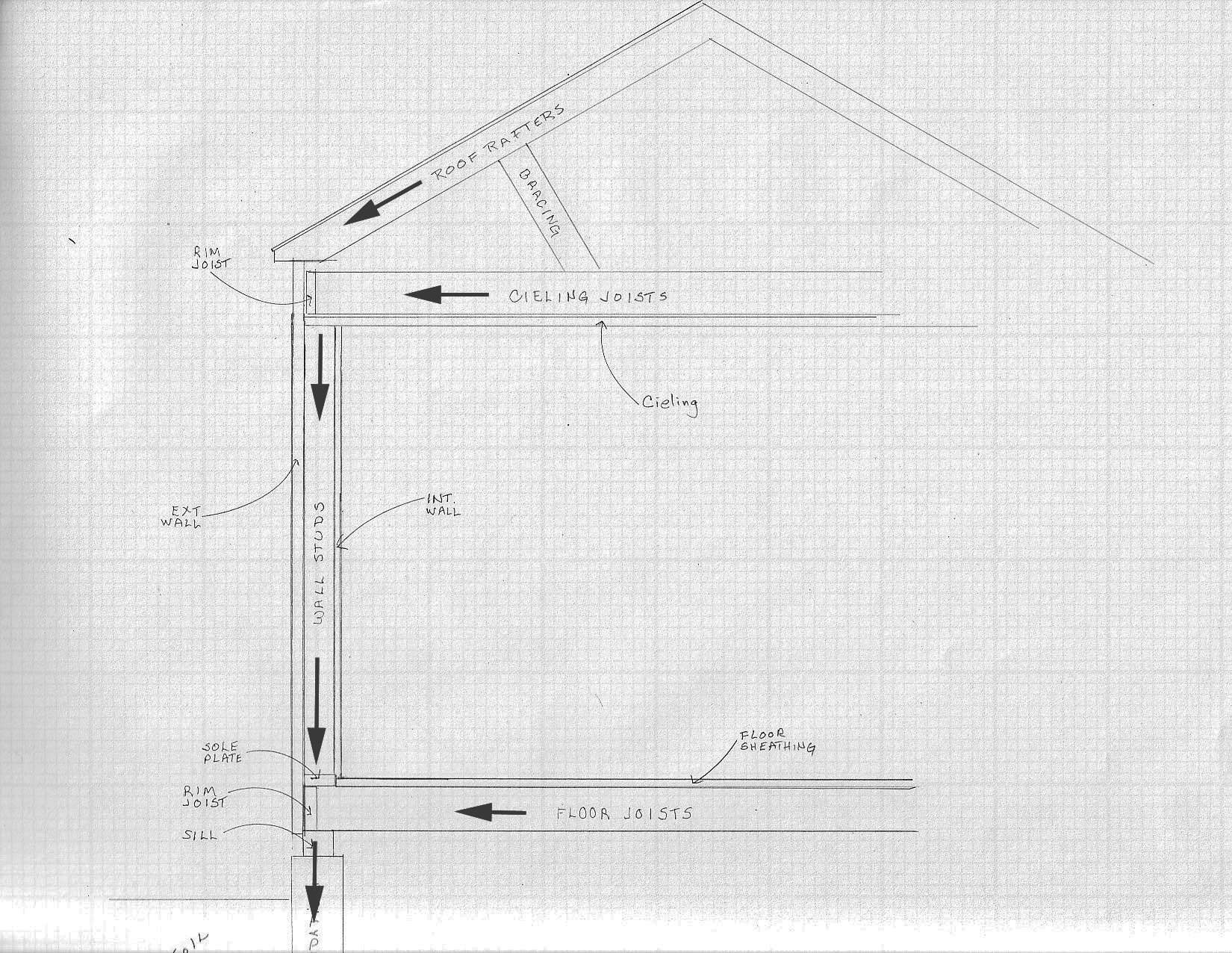

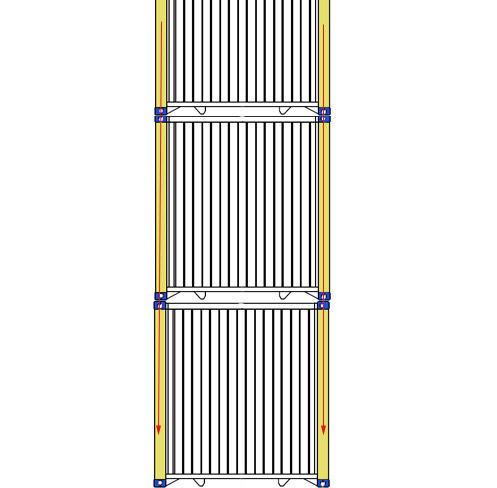

In the case of homes (big wooden box) with typical raised platform construction, in its simplest form, the design can easily support the weight of materials and contents when build out of 2X lumber, framed to specification, the load path will look like the diagram below. The raised platform is an efficient design, with the walls attached directly to the framed floor platform on each level.

A shipping container (big steel box) has the same design goal as a house; safely support the weight of the material and contents. But the design specs are a little more rigid, calling for them to be stacked up to nine high.

The engineer, taking advantage of the strengths of steel, designs a simple column that is strong enough to support the entire stack of 9 containers on four 6”x6” post ends, simple column and beam construction to support extreme loads under extreme climatic conditions.

In housing this type of construction method was popular in the good old days when we had massively strong timbers in dimensions that allowed them to span long distances, or today, when architects build those multi million dollar modern homes with the walls of glass and drop dead gorgeous views they will utilize a steel post and beam construction, post and beam wood construction today is more common in barns that houses.

Deconstructing a shipping container is a good way to understand the underlying engineering principals, and,

if you plan to incorporate used containers as an engineered element in your structural plans you will need to

explain the materials, construction, strength and load capacities of the various container elements, in

engineering terms, right there on your plans.

The simple truth is that these blueprints are a vital way to prove that your shipping container structure is capable of meeting

the same load requirements as specified for traditional residential construction. When you can do this you are home free as long as

your projects it meets all other relevant requirements as well. In the eyes of the building department’s engineers

this will deem the structure safe for occupancy.

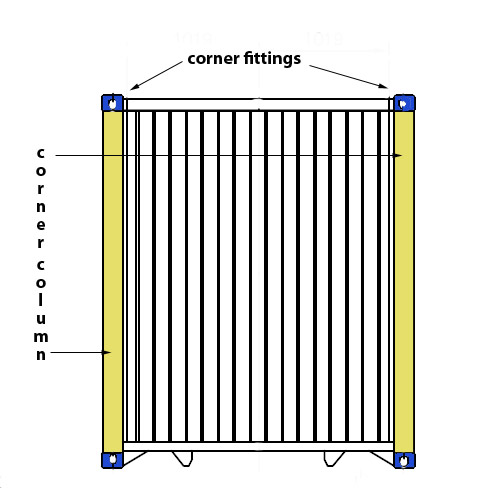

The unique needs of the cargo industry resulted in a container design that allows the bottom container to absorb and transfer the load of multiple containers stacked on top of it. Thus, in a shipping container the vertical load is transferred via the base beams out to the corner posts, or columns, and corner fittings on down to the ship’s desk. The corner fittings are an integral part of the load-bearing column/post. It’s important to note that the design allows the containers to only make contact at the corner posts, so the bottom containers corner columns support ALL the weight of the containers stacked on top of it, making the columns the strongest part of the entire container. The cargo loads are carried by the floors and transferred out to the corner columns and corner posts, the roofs of the containers carry none of the weight of the container above.

The roof load of an ISO container is on the complete other end of the strength scale from the corner column/post. Here, the value of 300kg (660lbs) was selected by the ISO to represent the weight of 2 men with tools working on the roof. It’s easy to see that the columns and corner castings of an ISBU are by far the strongest part of the assembly. The roof and sidewalls serves as a shear plane rather than as a load-bearing member and should not be relied on to support any serious loads even when supported by the intact sidewall.

Deviations from this form of stacking must be carefully considered from the perspective of load paths. As the diagram above plainly shows, when stacked as designed the bottom container can support a tremendous load on it’s 4 corners. When you stack them transversely or cantilever them you effectively compromises the strength of the whole unit.

Good container home designs will provide second floor loads with a path to the foundation via the corner columns, or, if stacking transversely, via separate support columns or walls extending the length of the upper floor columns. Cost effective foundation choices include concrete perimeter for colder climates, and pier foundations for more temperate climates, or where flooding is an issue.

Scroll down for next chapter