If you have downloaded you state's building codes you can see that it is a hefty collection of rules and regulations. The 2006 IRC’s runs to over 700 pages, and not once does it mention shipping containers as a building material. In some people's view this is interpreted to mean it’s not possible to get building permits for homes incorporating shipping containers.

But if you took the time to actually read the relevant sections you would find several sections of the code that allow for alternative construction methods. So this is untrue; in reality the IRC code provides several provisions for non-traditional designs and materials.

“Alternative materials, design and methods of construction and equipment. The provisions of this code are not intended to prevent the installation of any material or to prohibit any design or method of construction not specifically prescribed by this code, provided that any such alternative has been approved. An alternative material, design or method of construction shall be approved where the building official finds that the proposed design is satisfactory and complies with the intent of the provisions of this code, and that the material, method or work offered is, for the purpose intended, at least the equivalent of that prescribed in this code. Compliance with the specific performance-based provisions of the International Codes in lieu of specific requirements”

The simple translation is that if you can prove that your shipping container structure is capable of meeting the same load requirements as specified for traditional residential construction you are home free as long as it meets all other relevant requirements as well. In the eyes of the building department’s engineers this will deem the structure safe for occupancy.

Spells out the performance specs, load standards and test procedures a container manufacturer has to meet when designing a shipping container. The ISO stress tests build in a safety factor and then certify that that manufacturer’s containers meet their requirements for shear load, stacking loads, transverse rigidity, racking forces, etc. Once certified by the ISO a manufacturer’s containers carry a serial number and an ISO registration shield with the load limits displayed to assure user that the container meets the rigid ISO standards and will perform as expected.

This ability is supported by IRC 104.11.1

“Tests - Whenever there is insufficient evidence of compliance with the provisions of this code, or evidence that a material or method does not conform to the requirements of this code, or in order to substantiate claims for alternative materials or methods, the building official shall have the authority to require tests as evidence of compliance to be made at no expense to the jurisdiction. Test methods shall be as specified in this code or by other recognized test standards. In the absence of recognized and accepted test methods, the building official shall approve the testing procedures. Tests shall be performed by an approved agency.“

So it could be argued that citing the ISO test standards is acceptable according to the code. Keep in mind that ISO reference standards are already recognized by the IRC. This may allow you to use the ISO test data in ISO/TR 15070: 1996 as proof tests of the claims you are making about the load capacities you are showing on your structural plans for the engineered elements of your plans. HOWEVER, any modifications to the container still have to be accounted for engineering wise.

Since a large part of your project will be steel it’s worthwhile to have some background on steel construction so you can understand and utilize a generally accepted steel construction methods, which are more likely to lead to building department understanding and approval. Since a large part of your project will be steel it’s worthwhile to have some background on steel construction so you can understand and utilize

Steel is the most versatile building material from the structural engineer’s perspective and is the material of choice for it’s uniform quality, and dimensions. Its one weakness is the fact that it loses strength at high temperatures. Many one, two and three story structures contain structural steel components. The most common method of steel construction is column and beam, just like a shipping container. Of the two categories of steel, structural and non-structural, we will concern ourselves with the structural components. The non-structural components would consist of items like railings and the like.

Structural steel parts are listed in the Code of Standard Practice, or CSP, which is published by the American Industry of Steel Construction, or AISC. He parts listed in the CSP are all available thru steel fabricators. According to the code the term “Structural Steel”, when used in construction documents, consists of only the items in the following list.

Anchors for structural steel

Bases of structural steel

Beams

Bearing plates for structural steel

Columns

Crane rails, stops, splices, bolts and clamps

Door frames constituting part of a structural frame

Expansion joints connected to a steel frame

Fasteners

Permanent shop bolts

Shop bolts for shipment

Field bolts for permanent connection

Floor plates connected to structural steel frame

Girders of structural steel

Girts

Grillage beams and girders

Hangers of structural steel

Leveling Plates

Lintels shown on framing plans

Machinery foundations

Marquee framing

Monorail beams of structural shapes attached to frame

Permanent pins

Purlins

Separators, angles, tees, clips essential to structural frame

Shear connectors

Steel cables forming a permanent part of structural frame

Struts

Supports for piping, conveyors, and similar

Suspended ceiling supports of steel structural shapes 3 inches or greater in depth.

Tie, hangers, and sag rods forming part of frame

Trusses

Due to its non-combustible nature, steel framing is a requirement under the Universal Building Code for certain types of buildings; such as residential structures over three stories.

Rolling mills produce the structural steel members that are called hot rolled shapes. The ASIC Manual of Steel Construction provides the dimensions and structural properties of each shape. The shapes are designated by a letter designation.

Figure 1 (S) American Standard Beam

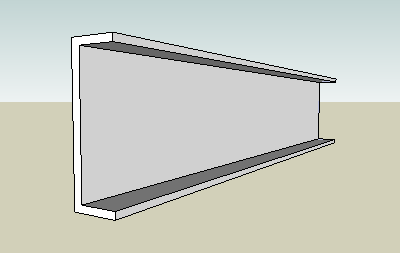

Figure 2 (W) Wide Flange Beam

Figure 3 (C) American Standard Channel

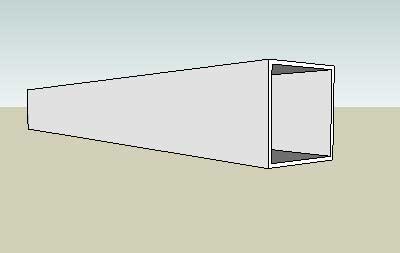

Figure 4 (TS) Structural Tube

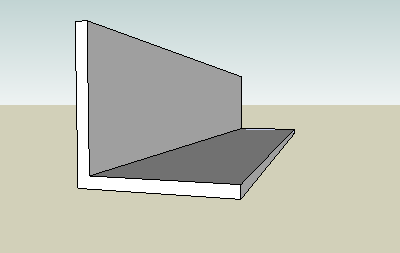

Figure 5< (L) Equal Leg Angle

There is also the (M) designation, which represents beams with shapes other than the Normal W or S shape. Using these standard shapes, as columns and beams, is how most normal steel construction is erected.

Structural steel is classified by its chemical composition. There are two general types, carbon steel and alloy steel. Carbon steel is used mainly in construction. Alloy steel is used where corrosion may be a problem.

When a mill produces steel members it also creates what is called a “Certified Mill Test Report” describing the chemical composition and test results performed on samples. These test reports are used to verify the quality and strength of the steel.

The American Society of Testing and Materials (ASTM) publish the specifications that control the properties of structural steel. Names such as ASTM A36, A242, and A441 are ASTM designations for different types of steel.

Today ASTM A36 is the standard grade of steel used in building construction.

As a point of comparison a shipping container’s corner columns are usually made of steel typically corresponding to ASTM A-572, with a yield stress of 47,000 psi. The corner column is actually are tested to a load of 190,480 lbs, and an ultimate stress of 70,000 psi.

The corner fittings at the top and bottom of the corner columns are tested to 203,680 lbs. Corner fittings are typically cast and machined from A-216 steel, which has a minimum specified yield stress of 40,000 psi.

One technicality you should be aware of is the fact that if you lack the CMTRs from the mill that rolled your steel you MAY not be allowed to use the steel, OR, you MAY be required to have lab tests performed on samples cut from your used steel, OR, you may be allowed to use the steel but be limited to rating it at only 50% of its original strength.

This will depend entirely on you local building department and how rigid they choose to be.

As you can see, being prepared when you go to the building department is vital. If you have the knowledge and correct information your interactions with the guys behind the counter will be much more productive and your odds of success will be greatly improved.

Scroll down for next chapter